SUNTECH Tension Control Fabric Inspection Machine Greatly Improves Fabric Inspection Quality

With the improvement of quality of life, customers have higher and higher requirements for clothing, and clothing manufacturers have naturally higher and higher quality of raw material fabrics. In addition to high-quality and high-standard production processes before leaving the factory, cloths also need to be strict The fabric inspection.

The purpose of fabric inspection is to make the finished garments produce as few defective products as possible. When the fabric enters the factory, the quality and quantity of the fabric must first be inspected. Since the quality of the grey fabric is directly related to the quality and output of the finished product, it is necessary to check the number, size, density, batch number, Whether the linear density meets the requirements, the grey fabrics are inspected one by one according to the standards during the fabric inspection. Various defects that affect the quality of the finished product, such as color patterns, missing needles, holes, and oil stains, must be marked and quality recorded. If fabric inspection is not carried out, it will affect the quality of subsequent production and finished garments.

If the width of a roll of cloth is close to the specified minimum width or the width of the cloth is uneven, the number of inspections on the roll width should be increased. If the roll width is less than the specified minimum purchase width, the roll will be considered unqualified.

For woven fabrics, if the width is 1 inch wider than the specified purchase width, the roll will be deemed unqualified. But for elastic woven fabrics, even if they are 2 inches wider than the specified width, they can be considered qualified.

For knitted fabrics, if the width is 2 inches wider than the specified purchase width, the roll will be deemed unqualified. But for the stretch frame knitted fabric, even if it is 3 inches wider than the specified width, it can be considered qualified.

A major defect will be regarded as a three-point or four-point defect. If the cloth has obvious loose threads or tight threads on a selvedge, or there are ripples, wrinkles, creases or creases on the main body of the cloth, these conditions will lead to When the cloth is unfolded in the usual way, the cloth is uneven, and such a roll cannot be rated as a first-class product.

The entire fabric inspection process has many links and cumbersome operations. It must also ensure the accuracy, low error rate and high efficiency of the fabric inspection. In addition to the high requirements for the experience, technology and patience of the fabric inspection workers, the requirements for the fabric inspection machine are also very high. . For example, the width, weft skew and weft bending inspection are all related to the tension of the fabric, which requires the fabric inspection machine to be able to control the tension of the cloth in order to ensure the accuracy of the fabric inspection.

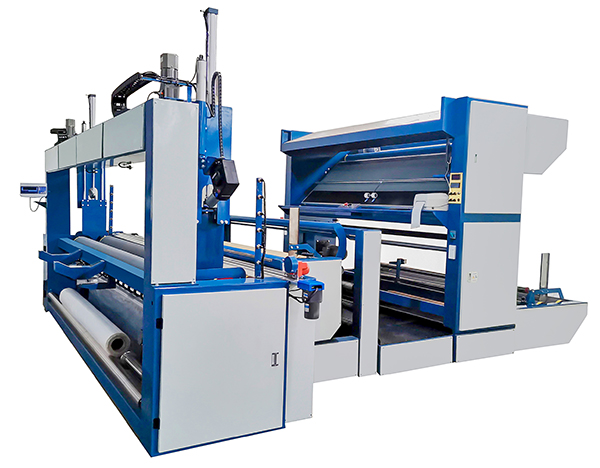

Suntech ST-KFIM OPEN WIDTH KNITTED FABRIC INSPECTION MACHINE can automatically control the tension. The running speed is controlled by PLC. The end of the cloth roll is connected to the output shaft of the magnetic powder brake through a mechanical device. The braking force of the magnetic powder brake is adjusted by controlling the current. The tension controller is controlled by the PLC, and the proximity switch is used as a speed measuring device. Form an effective closed-loop control, which can accurately and real-time adjust the size of the unwinding braking force according to the change of the cloth roll inertia, so as to make the cloth surface tension constant to meet the needs of automatic fabric inspection. Compared with other tension control fabric inspection machines, the tension adjustment of this equipment is more stable, accurate and fast, which can effectively improve the detection efficiency of cloth surface defects.

(SUNTECH ST-KFIM OPEN WIDTH KNITTED FABRIC INSPECTION MACHINE)

Comments

Post a Comment